-

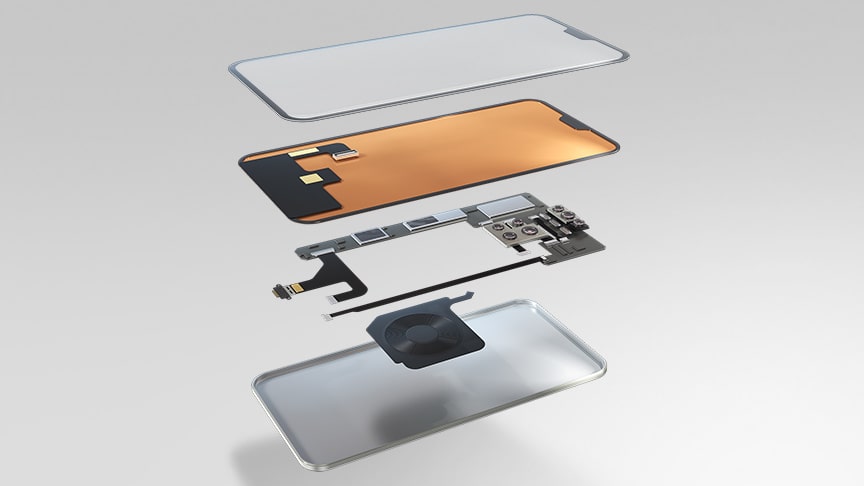

Developed by fully exploiting our unique technologies,

TATSUTA’s functional films have gained an overwhelming

global market share at the forefront of mobile devices. -

We have created an EMI shielding film for FPC applications, which protects the internal circuits of electronic mobile devices such as smartphones and tablet terminals, and gained an overwhelming global market share. We are also actively working on the expansion into the automobile field, where digitalization is accelerating, and the development of EMI shielding films for high-speed signal transmission for 5G, a new communication standard.

Watch the business introduction video.

Acquiring certification for business continuity management systems based on ISO22301

TATSUTA Electric Wire & Cable Co., Ltd. established its business continuity management system in July 2016 and obtained third-party certification to ensure continuing and quickly restoring the business and minimizing the impact on products and services for customers, in the event of not only natural disasters such as large-scale earthquakes, but also events such as supply chain disruptions, pandemics, and information system failures including cyber attacks.

Outline of BCMS certification

| Registered organization | TATSUTA Electric Wire and Cable Co., Ltd. System & Electronics Division Functional Materials Division and related departments |

|---|---|

| Location | Tatsuta Technical Center, Head Office, Kyoto Factory, Sendai Factory |

| Scope of registration | Production and sales of functional films |

| Registration Number | BCMS 653311 |

| Applicable standard | ISO 22301:2019 & JIS Q 22301:2020 |

| Date of initial certification and registration |

July 25, 2016 |

| Renewal date | July 25, 2022 |

| Certification body | BSI Group Japan K.K. |

Acquiring certification for information security management systems based on ISO27001

Based on the recognition that maintaining and improving information security of the company information held is an important management issue, TATSUTA Electric Wire & Cable Co., Ltd. established an information security management system in January 2023 and acquired third-party certification to maintain and enhance social trust and increase corporate value.

Outline of ISMS certification

| Registered organization | TATSUTA Electric Wire and Cable Co., Ltd. Electronic Materials & System Equipment Group Functional Materials Division |

|---|---|

| Location | Tatsuta Technical Center, Information System Department, Kyoto Factory, Sendai Factory |

| Scope of registration | The development, design and production of functional film |

| Registration Number | IS 779925 |

| Applicable standard | ISO/IEC 27001:2022 & JIS Q 27001:2023 |

| Date of initial certification and registration |

January 7, 2023 |

| Renewal date | April 11, 2025 |

| Certification body | BSI Group Japan K.K. |

TATSUTA films, world-class quality

-

Functional films

EMI shielding films for FPC applications We have a wide range of products, EMI shielding films to protect mobile devices from electromagnetic wave causing malfunction and others to give additional functions to a circuit board.

- EMI shielding films for FPC applications

- EMI shielding films for FFC applications

- Ground strengthen film

-

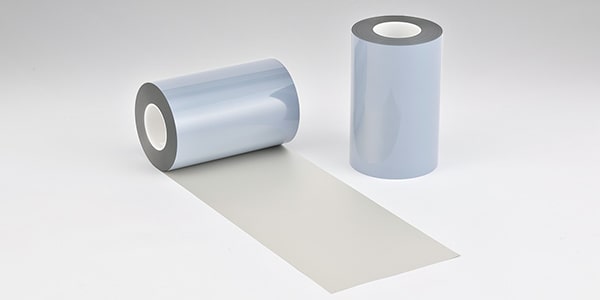

Conductive adhesives

Conductive bonding films These are conductive adhesives used at the point where electrical connections are required, to enhance the grounding of electronic circuits and connect electrodes.

- Conductive bonding films

- Conductive double-sided adhesive tapes

- EMI shielding tapes

- TOPICS

-

-

Quick and stable supply of

functional films supported by

a monthly production capacity

of 1.5 million square meter -

Inspectors are checking quality. To maintain an overwhelming global market share of functional films, we have newly established the Sendai Works and secured a monthly production capacity of 1.5 million m2 by combining three plants in Japan. This move will help us more quickly and stably supply our films to meet increasingly growing markets of electronic mobile devices such as smartphones.

Development of our own quality inspection system We carry out strict quality control by checking with the eyes of both humans and machines in each process and before shipment.

-

Quick and stable supply of

- For inquiries about functional films