Development of Products and Services

That Resolve Social Issues and Satisfy Customer Needs

At the TATSUTA Group, we develop products that satisfy customer needs, and products and services that help to resolve social issues.

Electric Wire and Cable Business

We endeavor to improve the quality of overhead distribution cables for power companies and to increase productivity. We also meet the needs of society, such as considering the use of materials that help to achieve a stable supply and to reduce our environmental impact. Additionally, in the area of wires for industrial equipment, we are not only expanding our product types based on various actual needs, but also developing unique products that contribute to the stable supply of electricity and to environmental and social issues.

Examples of products and services

Social needs : Improving the efficiency of onsite work

- かるまげ™ 難ゃ燃 (Karu Mage Nanyanen)

-

The allowable bending radius is half of the typical, which is particularly useful for wiring in narrow spaces. In addition, because of its excellent flame resistance, it is the optimal cable for data centers, power plants, and surrounding cubicles.

- かるまげ “Karu Mage” is a trademark of TATSUTA Electric Wire & Cable Co., Ltd., registered in Japan.

Social needs : Supporting the advancement of FA and robot markets

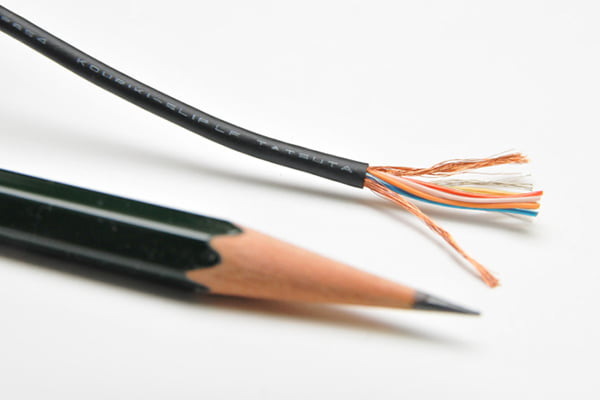

- Thin-diameter KORIKI™ high-strength cables

-

Cables with excellent tensile strength and repeated bending strength, made from our unique high-strength copper alloy. They are ideal for use in space-saving environments, such as various FA equipment, machine tools and other moving parts, cableveyors, and revolving parts on robots.

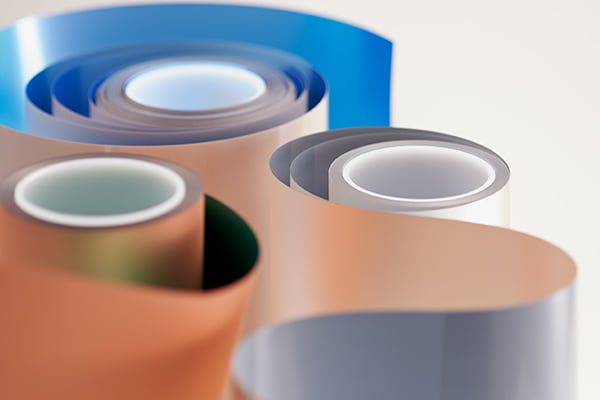

Electronic Materials Business

In functional films and functional pastes, we engage in material development, product development, and the development of processing technologies for these. We also pursue product development and application development targeting fields related to electronic materials and new fields, including coordination with external organizations in Japan and overseas. In bonding wire, we promote copper wire and silver wire product development.

Examples of products and services

Social needs : Supporting the evolution of smartphones

- Shielding film for high step/uneven surface 〈WILMINA™ SF-FT™ 6015-US-C〉

-

Cameras that have evolved with the development of smartphones. With the higher functionality of smartphone cameras, high shielding has also become required on the high-step substrates used in camera modules. Resistance to ultrasonic washing in the camera module manufacturing process is also necessary. WILMINA™ SF-FT™ 6015-US-C satisfies the needs of high shielding, high-step/uneven surface, and ultrasonic cleaning resistance.

- “WILMINA” is a trademark of TATSUTA Electric Wire & Cable Co., Ltd., registered in Japan and other countries.

Social needs : Supporting advanced electronics

- SC series low-temperature curable conductive paste

-

This is a conductive paste that can be cured in the low temperature range of 60℃-80℃. Its use is expanding in plastic substrate interlayer connection applications and component packaging applications, and it will support the evolution of electronics in various fields.

Social needs : Supporting the semiconductor market through higher functionality of ultrafine wire

- Silver wire for NAND memory

-

In response to a request for an alternative to expensive gold wire, we began mass production of highly reliable, highly conductive, low-cost silver wire for NAND memory in Japan. NAND memory demand is expanding in smartphones, tablets, and data centers, and to address BCP and meet the demand overseas users, we have begun to build a mass production system overseas (Malaysia).

Other Businesses

We engage in R&D for the commercialization of medical equipment materials and R&D for medium- to long-term product development.

Examples of products and services

Social needs : Advanced medicine

- Medical equipment materials

-

The Company began to manufacture and sell optical fiber interferometer modules for optical coherence tomography (OCT) in 2013 and medical cables in 2017, and we have steadily achieved results. Currently we engage in development and commercialization of high-function tubes and optical fiber devices to improve convenience for medical professionals. In March 2022, we built a production line for optical fiber probes for medical applications at our Kyoto Works, and have begun manufacturing and sales.

- Optical fiber probes

- New cancer treatment methods using light irradiation, such as photodynamic therapy (PDT)*1 and photoimmunotherapy (PIT)*2, are becoming popular alternatives to surgery and chemotherapy. The beam profile (which indicates the intensity distribution of the laser light) of the optical fiber probes*3 supplied by the Company is based on a frustum cone shape, resulting in a smooth profile, enabling extremely uniform and efficient frontal irradiation of the tumor tissue at the target site.

- A minimally invasive treatment that has little effect on normal tissue and reduces the physical burden due to being a local treatment that causes degeneration and necrosis of the tumor tissue at the target site by putting a photosensitizing agent with high tumor affinity into the body and projecting laser light onto the area.

- A new cancer treatment method that combines photodynamic therapy and immunotherapy.

- A tool used to project a laser at a lesion.

Social needs : Prevention of environmental pollution and protection of human health

- Dioxins analysis

-

We measure and analyze dioxins that are toxic and have a major impact on the human body. To ensure highly reliable measurement and analysis, at the Tatsuta Environmental Analysis Center, we obtained Specified Measurement Laboratory Accreditation (MLAP) from the National Institute of Technology and Evaluation (NITE).

Strengthening quality assurance systems

The Group will continue to respond to customer expectations by consistently providing superior quality.

The TATSUTA Electric Wire & Cable Group has acquired ISO 9001 certification, appropriately operates a quality management system (QMS), and performs regular audits. We have also constructed a proprietary QMS tailored to our businesses and undertake a variety of initiatives to provide safe and high-quality products and services.

Electric Wire and Cable Business (Wire & Cable Group, TATSUTA Electric Wire & Cable Co., Ltd.)

At the Wire & Cable Group, we manage the quality of raw materials, manufacturing processes, and finished products so that customers can use our products with peace of mind. By maintaining public certifications, such as ISO and JIS, and by undergoing customer audits, we can prove that the quality of our products complies with the demands of customers.

| Initiative | Details |

|---|---|

| Maintaining and managing public certification and customer accreditation | Public certifications, such as ISO and JIS, and the needs of customers change along with social, environmental, and economic changes. To respond to these, we are improving our quality management system. We also continue to undergo quality audits by public certification institutions and customers to prove that our quality management system complies with quality requirements. |

| Strengthening the quality management system | A tremendous amount of data is generated in manufacturing products and managing quality. We have established a computer system for aggregating the data and are improving the accuracy and speed of data analysis by using numerical analysis software. The analysis results help to check that quality is maintained, that the impact on the environment is mitigated, problems are solved, and that conditions for making products safely are established. |

| Finished product inspections | Finished products are inspected for product structure, electrical properties, and characteristics of materials used, based on specification forms describing customer requirements. Inspections are carried out according to procedures determined by qualified quality inspection personnel who determine acceptability. |

| Process control | We operate a computer system to manage production lines. This system can send instructions to manufacturing processes, check the progress of processes, and contact those concerned immediately if an abnormality should occur. Manufacturing personnel remove the abnormality, and quality personnel conduct an investigation and check to prevent its outflow from the company. |

| Improving quality and enhancing customer satisfaction | Quality claims and defects are addressed by thoroughly investigating the cause of the problem through “why-why analysis,” to prevent the problem from recurring. |

| Quality management education |

We added the following new education topics to our existing education on quality management methods.

|

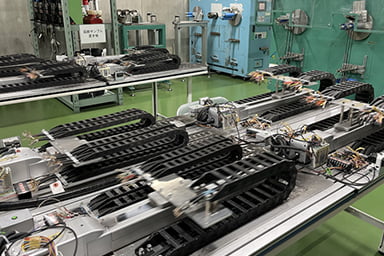

Electric Wire and Cable Business (Tatsuta Tachii Electric Cable Co., Ltd. and Chugoku Electric Wire & Cable Co., Ltd.)

At Tatsuta Tachii Electric Cable Co., Ltd., we investigate the true cause of defects and take measures to prevent recurrence through means such as why-why analysis and replication experiment verification, progressively standardize processes, review inspection methods, and strive to improve quality. As a result, we reduced the number of defects in the second half of the fiscal year ended March 31, 2023, by 23% from the first half of the fiscal year. Going forward, we will engage in initiatives to visualize equipment operating status, and we will endeavor to identify issues through analyses of equipment outages, further improve quality, and promote high-efficiency and high-quality systems.

At Chugoku Electric Wire & Cable Co., Ltd., we have proceeded with the review of inspection standards, and continue to engage in ensuring stable product quality through the implementation of low-variation inspections by image measuring devices.

| Initiative | Details |

|---|---|

| Enhancing inspection systems | We implement efficient and exact inspections using cutting-edge measuring instruments, including image measuring devices for structural measurement. |

| Increasing the precision of product lifespan forecasts |

For movable cables where superior flex and twist properties are required, we have compiled a proprietary database using historical data to increase the precision of product lifespan forecasts. We accommodate flex and twist testing requests from customers.

and twist testing device |

Electronic Materials Business

We have established flexible quality assurance systems, optimally suited to our enhanced product lineup. We also work towards more stable product quality through measures such as supplier audits, to ensure that we respond appropriately to the anticipated expansion of our supply chains.

| Initiative | Details |

|---|---|

| Verifications at the development stage | Electronic materials undergo design reviews and prototype evaluation (experiments and testing) before arriving at the final product. We work to reduce quality risk through stringent verification by the Quality Assurance Department and other relevant departments at each stage. We have also obtained the relevant permits for the development and manufacture of medical equipment materials. |

| Quality inspections |

We carry out the following inspections for each process.

|

| Quality management education | We are conducting activities to raise individual employee awareness of quality by providing quality management education through ENEOS Research Institute, Ltd. |

- For inquiries about ESG

- Social Report

-

-

Products and Services Resolving Social Issues and Satisfying Customer Needs/

Strengthening Quality Assurance Systems - Intellectual property

- Supply chain management/Strengthening BCP systems

- Human Capital and Diversity

- Promoting Measures for Safety and Health

- Coexistence and Co-prosperity with Local Communities

- Social Data

-

Products and Services Resolving Social Issues and Satisfying Customer Needs/