FBG optimized for single oscillation of

polarization-maintaining Fiber Laser

Fiber lasers are a high-performance laser technology that uses optical fiber as a gain medium to amplify and output light. Compared to conventional solid-state lasers and gas lasers, the advantages are as follow:

- High efficiency: As light is directly amplified within the fiber, energy conversion is highly efficience, which allows energy-saving operation.

- High reliability and stability: Optical fiber’s structure allows for easy thermal management, ensuring stable operation over long periods of time.

- Excellent beam quality: The use of single-mode fiber produces an extremely narrow laser beam, making it suitable for precision processing and measurement.

- Flexibility: Taking advantage of the optical fiber’s shape, compact and flexible designs are possible, allowing for miniaturized equipments used in tight spaces.

Product Details Information

Fiber Laser Resonator

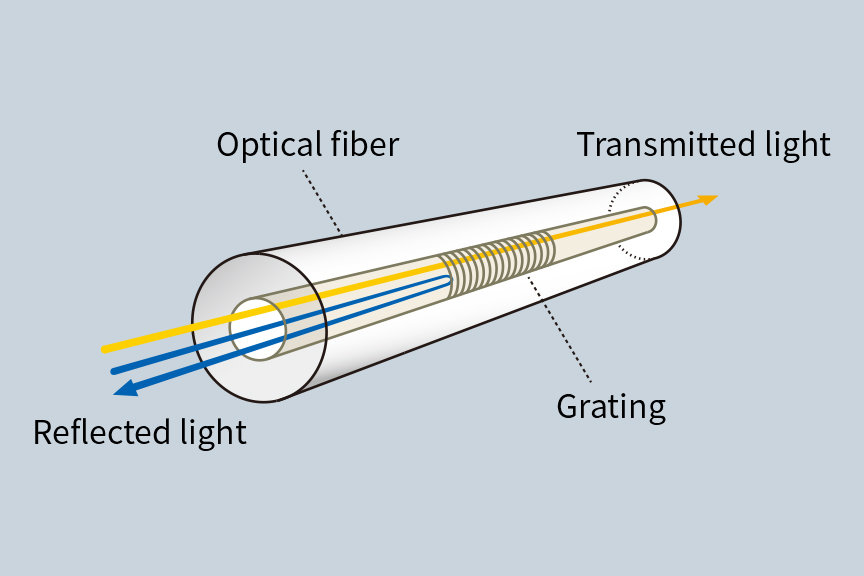

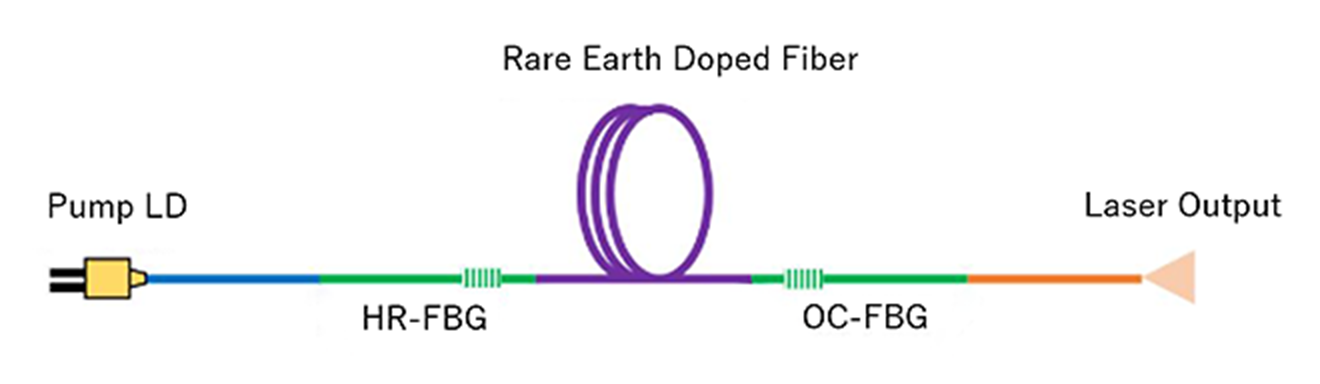

One method of configuring a fiber laser resonator is to use an FBG. The simplest system is one in which, a high reflectivity (HR)-FBG with reflectivity of >99% and an output coupler (OC)-FBG with reflectivity of 10 to 30%, are connected to a rare-earth doped fiber for amplification and forming a resonator.

When using it as a fundamental wave for harmonic generation using a wavelength conversion element such as PPLN, it is desirable to make it single-polarized to increase the efficiency of wavelength conversion.

One way to achieve single polarization is to incorporate an in-line polarizer (ILP).

However, there are some disadvantages to this method:

- The loss in the resonator increases, resulting in lower oscillation efficiency;

- The number of components increases, resulting in higher costs;

- ILP has poor durability against high power.

Thus, the orthogonal fusion method, which does not use ILP, is sometimes used.

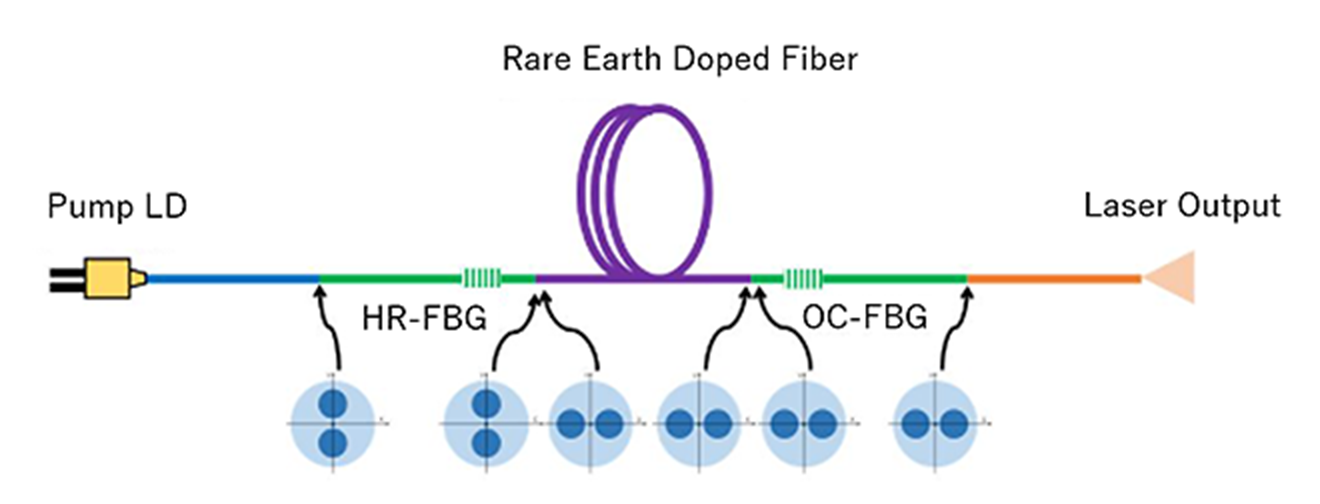

The orthogonal fusion method, is a method of constructing a resonator by fusing the polarization axes of HR-FBG and OC-FBG formed in polarization-maintaining fiber (PMF) with a 90° offset.

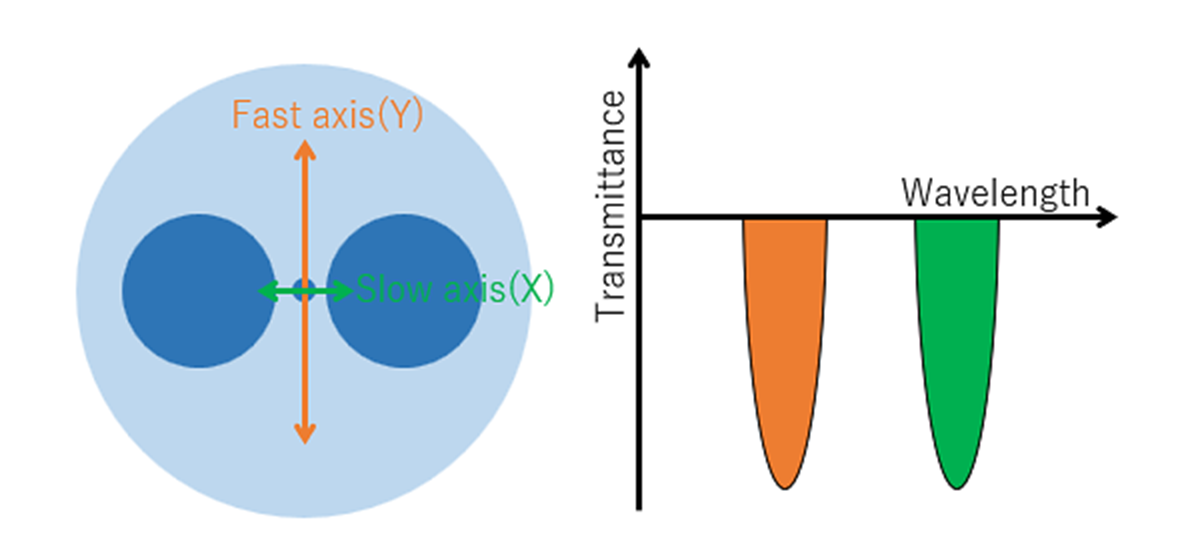

The Bragg wavelength of the FBG differs between the slow axis and fast axis due to the stress-applying part of the PMF.

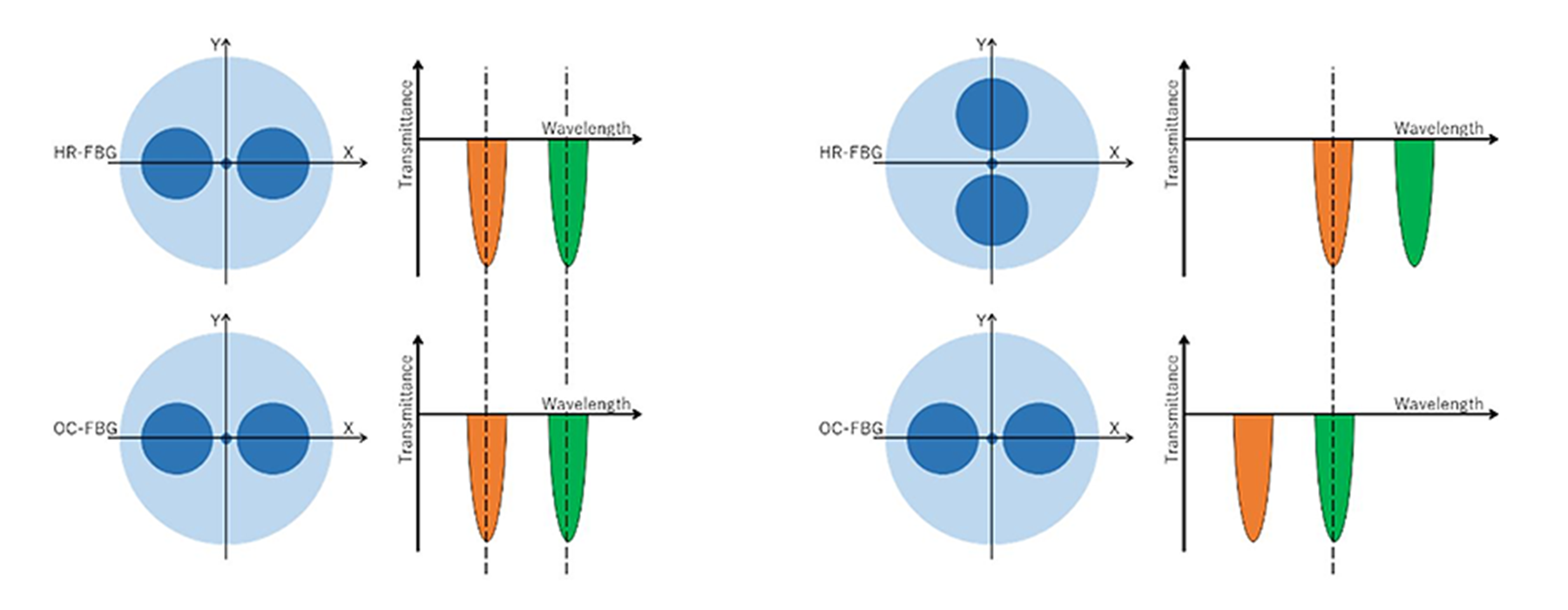

When two PMF-FBGs of the same wavelength are spliced together with their polarization axes aligned, they form resonators on the slow and fast axes, oscillating in two polarized beams (see the diagram below, left).

In contrast, when spliced orthogonally, with the slow and fast axes offset by 90°, only the wavelengths of the fast axis of the HR-FBG and the slow axis of the OC-FBG coincide, resulting in a single polarized beam (see the diagram below, right).

It is necessary to fabricate an FBG that matches the Bragg wavelengths of the fast axis of the HR-FBG and the slow axis of the OC-FBG.

However, with conventional masking methods, multiple phase masks must be prepared to change the Bragg wavelength, resulting in high initial costs.

Our proprietary optical system based on an interference system allows us to easily change the Bragg wavelength, allowing us to provide FBGs suitable for orthogonal splicing at no initial cost.

If the bandwidth of the HR-FBG or OC-FBG is wide, or if there is a wavelength mismatch between the HR-FBG and OC-FBG, oscillation may overlap with the polarization axis of the other, then single-polarized oscillation may not occur.

Tatsuta have experience provide FBGs optimized for single oscillation, please feel free to contact us if you are considering an FBG-based fiber laser.

- For inquiries about products