Fiber Bragg Gratings FBG

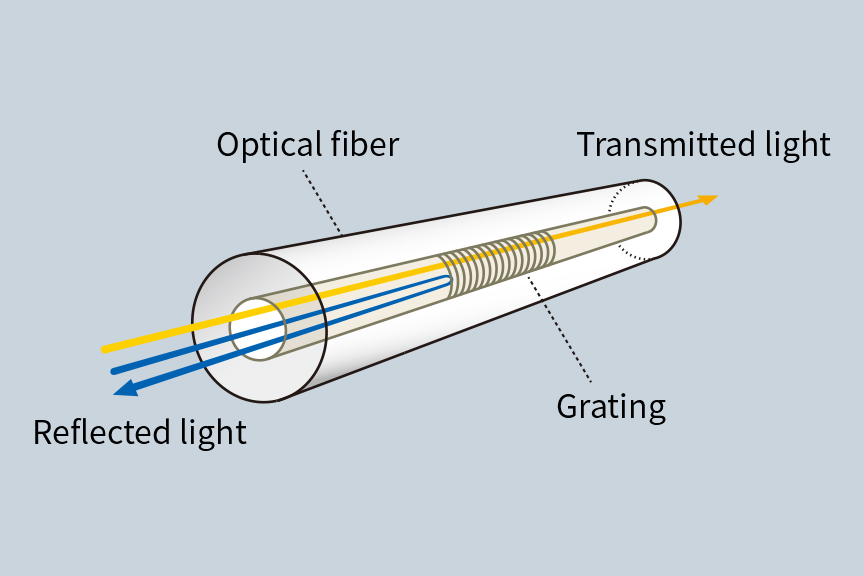

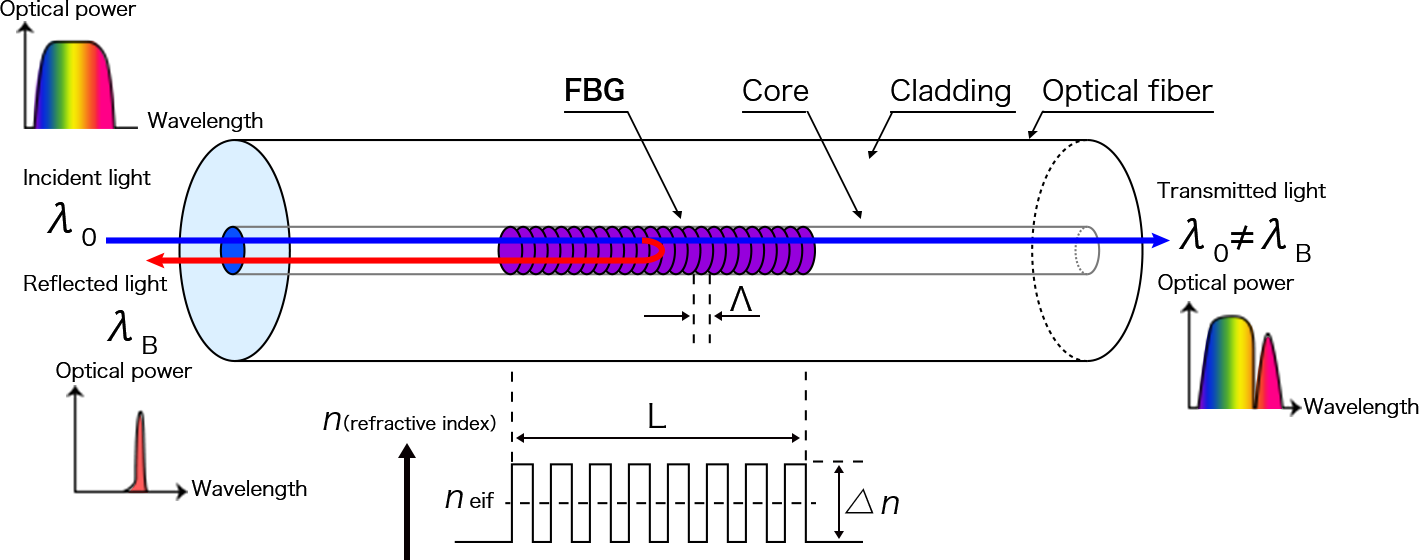

Fiber Bragg Gratings (FBG) are optical fiber type devices that form diffraction gratings in the core of an optical fiber and function as an optical filter. The FBG can select the light transmitted through the optical fiber core, and by separating the transmitted light from the reflected light, the FBG serves as an optical filter.

We uses a proprietary optical system to write the FBG into the optical fiber core, enabling a wide range of wavelengths to be selected and stable production.

Since we can manufacture products in a wide variety of wavelengths, we can accommodate individual specifications from a single prototype, so please consult with us.

Product details

Features

FBG customized manufacturing

We manufacture from single prototype to mass production at our own manufacturing facility in Kyoto plant.

We are one of the few manufacturers that offer a full range of services from prototyping to mass production.

FBGs are used in strain sensors and laser amplifiers, but they are also being developed and adopted in places (oil complexes, thermal power plants, nuclear power plants, chemical plants, gas storage facilities) where it is difficult to apply electric sensors due to their poor resistance to electromagnetic waves, corrosion, and explosion protection, as well as in specific applications. For manufacturers who challenge and develop new applications, we provide the most suitable FBGs in small quantities based on our accumulated know-how, as well as reliability and quality.

Unique optical system

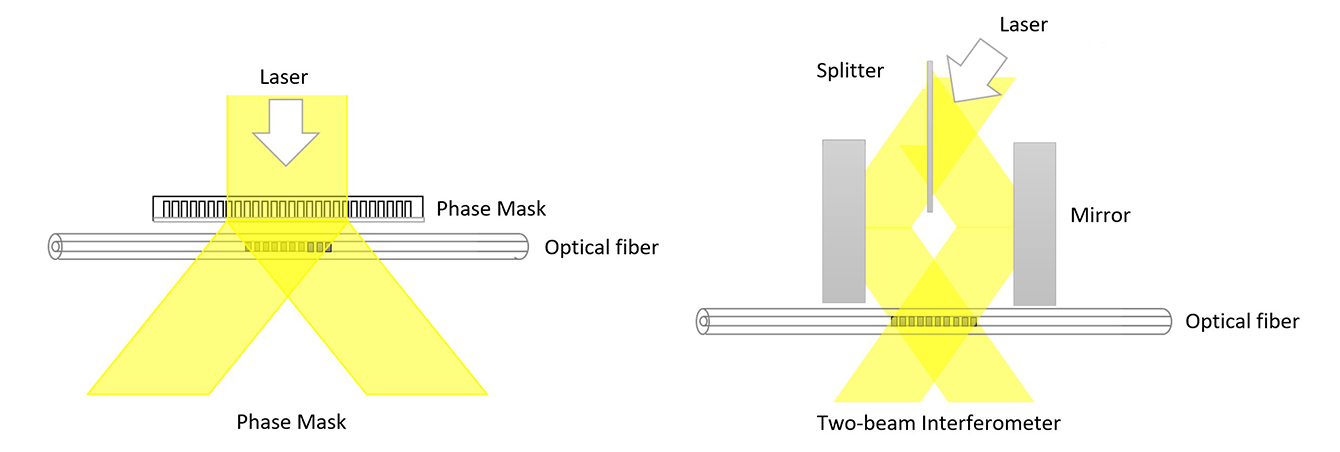

There are two main general manufacturing methods for FBG. We manufacture by our own optics.

- Phase Mask: In the phase mask method, the light incident on the phase mask is diffracted and the interference pattern between the diffracted lights is applied to the optical fiber to form an FBG. In the phase mask method, the wavelength of the FBG cannot be adjusted with the phase mask, but the characteristics of the FBG can be generated by the groove pitch of the phase mask, so the stability is high and mass production is possible. On the other hand, since the wavelength cannot be changed, a new phase mask is required for each wavelength, and an initial cost is required to manufacture an FBG with a new wavelength.

- Two-beam Interferometer: In the Two-beam Interferometer method, The wavelength can be changed over a wide range by adjusting the angle of the two light fluxes separated by a splitter with a mirror. Usually, optical axis adjustment of the optical system is very severe and time-consuming, making stable manufacturing difficult and not easy to maintain, making it unsuitable for mass production, and many FBG manufacturers do not use this manufacturing method.

We have constructed and manufactured a unique optical system that enables a wide range of wavelengths to be selected and stable production by overcoming the problems of the conventional phase mask method, which does not allow wavelength change, and the two-light flux interferometry method. In addition, phase masks are not required*, making it easy to consider prototyping and customization, and enabling high-mix, low-volume production with low initial costs.

*Phase masks may be required depending on the required specifications.

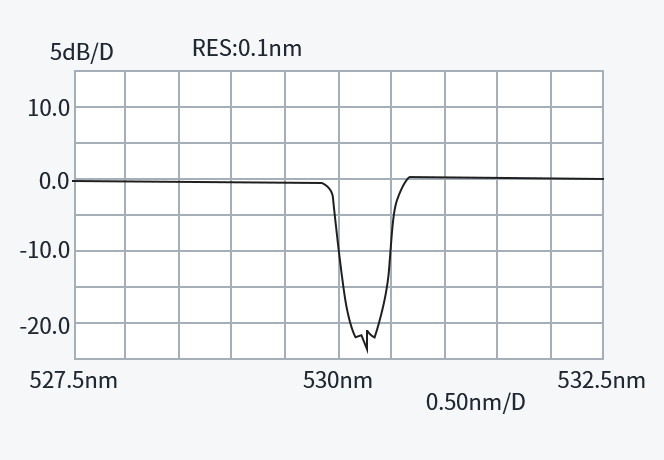

Wide wavelength range

FBG can be produced over a wide range of 530nm to 2100nm.

Temperature-independent

The variation of the center wavelength of FBG with temperature can be suppressed.

Basic specifications

Center wavelength

Overall 530nm to 2100nm (applicable to single-mode fibers at each wavelength)

Example*:

500nm band Nufern 460-HP

600nm to 700nm band Nufern 630-HP

800nm to 900nm band Nufern 780-HP

1000nm to 1100nm band Corning HI-1060

1200nm to 2100nm band Corning SMF28e+

*This is an example. Please refer to the catalog of each fiber and select the fiber that best suits your application.

Standard tolerance

Center wavelength ±0.2nm

Chirpable wavelengths 1000nm to 1100nm, 1500nm to 1600nm

Reflectance

5 to 95% ±2%

95% to 99% ±1%

Width-Half

Uniform 0.05nm to 1nm (depending on wavelength and reflectance)

Chirp 1nm to 5nm (depending on wavelength and reflectance)

List of equipment (light source and spectrum analyzer)

| Light source |

|---|

| 550nm ASE Light Source (520-560nm) |

| 850nm SLD Light Source (790-910nm) |

| 980nm SLD Light Source (910-1010nm) |

| 1050nm ASE Light Source (1000-1120nm) |

| 1310-1650nm SLD Light Source (1260-1750nm) |

| SC Light Source: technical use (480-2100nm) |

| Spectrum analyzer |

|---|

| For short wavelength band (400-1200nm) |

| For long wavelength band (1200-2200nm) |

| For normal bandwidth (700-1700nm) |

Application examples

-

Short-wavelength filter

-

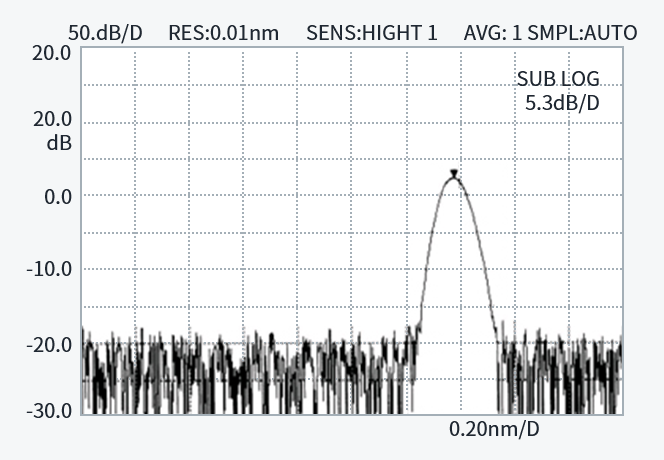

FBG wavelength locker (pump stabilizer)

It is an external resonator used to stabilize the emission wavelength and output. There is no restriction on the center wavelength.

-

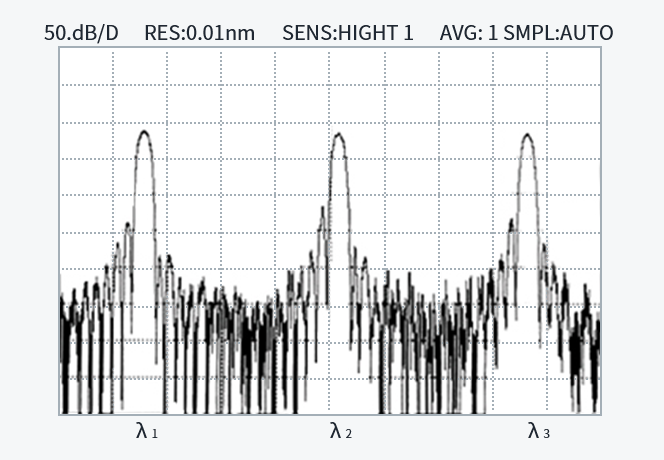

Multi-layer FBG

Create FBGs with arbitrarily different reflection wavelengths in a single optical fiber.

Standard products (example)

| Center wavelength | List of articles | Application | Specification |

|---|---|---|---|

| 790-910nm | Trigger | OCT | Specification sheet526KB |

| 980-1120nm | Trigger | OCT | Specification sheet526KB |

| 1260-1750nm | Trigger | OCT | Specification sheet517KB |

| 1000-1100nm | Resonators | Fiber laser | Specification sheet535KB |

| 1500-1650nm | Filter | Communication | Specification sheet562KB |

| 1500-1600nm | Sensor | Communication | Specification sheet526KB |

Structure and specifications

- For inquiries about products